Casting powder Raysin 200

- Free shipping from €0.00

- Klimaneutraler Versand mit DHL GoGreen

- Sicherer Kauf auf Rechnung

- 30 Tage Geld-Zurück-Garantie

- Kostenlose Abholung beim Händler

- Kostenlose Rückgabe

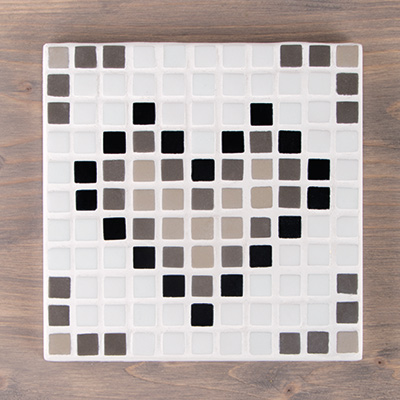

Trendy castings with a smooth, ultra-matt surface finish are created in a jiffy. Raysin is an air-hardening, odourless as well as food-safe casting powder and consists of all-natural calcium sulphate, which is why it is harmless and therefore also safe for casting with children. Moreover, Raysin is very easy to demould.

The casting compound Raysin 200 impresses with its high bending strength of 200N/mm² and is particularly suitable for casting larger items such as figurines, decorative tiles, bowls and the like.

Numerous casting moulds can be found within our range with which masterful works of art can be achieved. Raysin is suitable for moulds made of plastics (PET + LDPE), latex, rubber and silicone. Colour pigments (item no. 35016...) with which Raysin can be easily dyed in many pastel colour shades can also be found with us. With labels made of natural rubber, you can also consider incorporating texts/messages or motifs in your castings.

Our Raysin craft kit "Raysin decorative pendant" (item no. 34416000) is a nice gift idea. This DIY kit contains all the necessary material for making a few beautiful decorative pendants.

Material characteristics:

Are items made from Raysin fire-resistant?

Raysin is hardly flammable and therefore ideal for making candleholders.

Does Raysin have to be baked in oven?

Raysin is open-air drying and does not have to be baked in oven.

Are items made from Raysin water-resistant?

Items cast out of Raysin absorb water and are therefore not suitable for constant water exposure, e.g. as flower vases or bird watering holes. A clear varnish (varnish spray, matt varnish or food-safe varnish) provides effective surface protection and makes it water-repellent. However, 100% waterproofing cannot be guaranteed, as these varnishes are applied by hand and cannot be baked in oven.

Are items made from Raysin weather-resistant?

Items cast out of Raysin are conditionally weather-resistant. They feature resistance to frost and heat, but their surface can be somewhat washed-out under continuous rainfall, when severe deposits of dirt and moss are to be expected. A clear varnish (varnish spray, matt varnish or food-safe varnish) provides effective surface protection, increases the weather-resistance and makes Raysin more resistant to external influences. However, 100% waterproofing cannot be guaranteed, as these varnishes are applied by hand and cannot be baked in oven.

Raysin 200 is available in different quantities:

item no.34405102 (400g), item no.3699000 (1kg), item no.34410102 (4kg), item no.34475102 (10 kg) and item no.34477102 (25 kg).

We also have Raysin 100 within our range. This casting powder has a less high bending strength (120N/mm²) than Raysin 200, which is why it is suitable for making small and filigree castings such as decorative pendants/tags, figurines and the like. Raysin 100 is also available in different quantities: item no.34406102 (400g), item no.3410302 (1kg), item no.34409102 (4kg), item no.34474102 (10 kg) and item no.34476102 (25 kg).

Casting in black? Our Raysin 250 BLACK ensures a jet-black colour and ultra-mat look. It is available in the following quantities:

item no.34479576 (1 kg) and item no.34480576 (4 kg).

Here's how to get started:

Processing temperature:

Cold powder or cold water extends the processing and curing time. This could impede the curing process, resulting possibly in a lower final strength. In order to avoid this, we recommend leaving the cold powder to stand overnight at ambient temperature (20°C). The optimum processing temperature for powder and water is between 18°C and 25°C.

Mixing procedure and casting:

The different hardness degrees (100, 200 & 250) have a direct effect on mixing ratios making them automatically different. The higher the degree of hardness, the less water needs to be added to the casting powder:

• Raysin 100: 1 part of water to 2.5 parts of Raysin 100

• Raysin 200: 1 part of water to 3.5 parts of Raysin 200

• Raysin 250: 1 part of water to 4 parts of Raysin 250

Air bubbles may occur when stirring Raysin 100, 200 & 250. To minimise their formation, we recommend pouring the ready-to-cast Raysin slowly into the mould (e.g. over the concave side of the spoon) so that from the outset only a light layer free of air bubbles emerges on the surface. The rest of Raysin can then be quickly poured in. After pouring in, tap gently on the mould to dislodge any air bubbles.

Please allow the casting compound to dry thoroyghly in the mould and also allow the cast object to harden fully in open air after demoulding. If the demoulded items remain slightly wet, they can discolour.

Tips for a neat finish of Raysin 100, 200 & 250

• After drying, rub off any excess powder with a dry cloth.

• As with Raysin 100 and 250, the non-smooth rear side of the cast item with Raysin 200 is more porous and has edges with minimal burrs. This issue can be resolved by sanding the rough surface with fine sandpaper.

• Please take into account that sanding hardened Raysin items - regardless of colour - causes so-called sanding dust, which can be wiped using a moist cloth and washing-up liquid.

Tips for the casting moulds

Whether it’s about casting first with black and then with white Raysin, or vice versa, we recommend cleaning the casting mould thoroughly with lukewarm water and some washing-up liquid right after casting. If you use only one of the latter, a quick cleansing of the mould is just enough.

Avoid breathing dust